Want to Subscribe?

Read Corporate India and add to your Business Intelligence

![]() Unlock Unlimited Access

Unlock Unlimited Access

Published: Sep 30, 2022

Updated: Sep 30, 2022

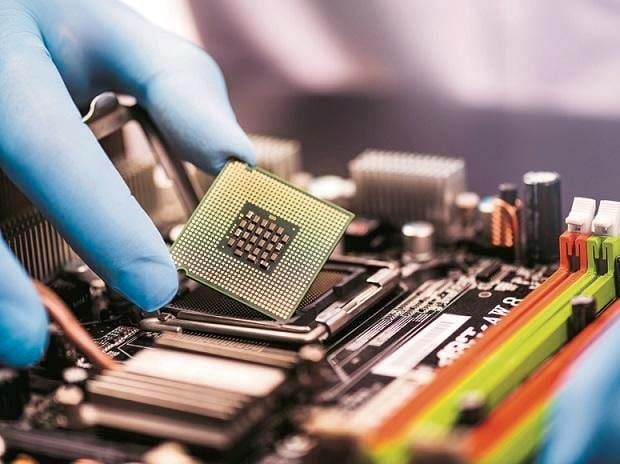

In today’s automated world, any country that aspires to be a global power needs to have a strong semiconductor manufacturing base. While domestic demand for semiconductors is estimated to touch $ 300 billion by 2026, India’s production capacity at present meets only 9 per cent of that demand. It is in this challenging scenario that the twin developments of a mammoth Vedanta-Foxcon semiconductor plant at Ahmedabad and an ISMC chipmaking plant in Karnataka promise to propel India into the league of chip-making hubs like Taiwan, China and South Korea. Fast-tracking this development is the Indian government’s incentivising semiconductor production with an outlay of Rs 76,000 crore over the next 5-6 years.

As one expert notes, India has a great chance for success in this cutting-edge space, considering its huge domestic demand for semiconductors and a large, technologically skilled workforce.

A new dawn will arise soon on the semiconductor space in India, taking the decades-old dream of the country emerging as a semiconductor manufacturing hub nearer reality. Even as domestic demand for semiconductor components is rapidly growing, reaching $ 119 billion in 2021 and estimated to touch $ 300 billion by 2026, the country continues to depend on imports to meet these requirements. The actual indigenous production of semiconductors does not meet more than 9 per cent of domestic demand and we have to depend on foreign countries – mainly China, Korea and Taiwan — for the remaining 91 per cent. If this situation continues, the gap between demand and supply will widen considerably, considering that while demand for semiconductors moves at a hare’s speed, domestic production is plodding like a tortoise.

“India is uniquely positioned to be an influential player in the semiconductor segment.”

— Narendra Modi

According to the India semiconductor market report, a joint research paper by the India Electronics and Semiconductors Association (IESA) and Counterpoint Research, the domestic market for semiconductors will balloon to $ 300 billion by fiscal 2026, forcing the country to rely more and more on imports.

However, a ray of light seems to have dispelled this gloomy prognosis. Oil-to-metals conglomerate and mining giant Vedanta, led by far-sighted entrepreneur Anil Agarwal, has given the country a semiconductor ‘gift’, so to speak. Vedanta has joined hands with Foxcon, a Taiwanese giant in the field of semiconductors and a supplier to Apple Inc, to set up a huge semiconductor manufacturing project at a cost of around $ 20 billion (around Rs 1.54 lakh crore). The plant will come up near Ahmedabad in Prime Minister Narendra Modi’s home state of Gujarat, and is expected to go on stream within the next two years.

What is more, last year the International Semiconductor Consortium (ISMC) announced that it would invest $ 3 billion to set up a semiconductor unit in Karnataka and signed an agreement with the state government. The unit will be set up in partnership with Intel-owned Tower Semiconductors. With both these plants going into production, India will not only be firmly placed on the global semiconductor manufacturing map but will, as the Modi government hopes, become a semiconductor hub in line with leading players in the space like Taiwan, South Korea and China.

With a view to achieving this aim, the government has devised imaginative and attractive policies. Last year, it announced a production linked incentive (PLI) scheme called Semicon India for semiconductor and display board production to attract chip manufacturers to the country. Through this programme, the government plans to spend around Rs 76,000 crore in semiconductor production over the next 5-6 years. The government is looking to provide financial assistance to companies that invest in semiconductors, display production and the design environment. Of course, India’s aspiration of becoming a global semiconductor manufacturing hub is not new. Back in 2005 when Dr Manmohan Singh was the Prime Minister, the country tried to attract semiconductor manufacturing giants to set up shop here. However, an uncertain political situation, unfavourable business conditions and bureaucratic hurdles kept them away. India’s attempts to lure chipmakers in 2017 and 2020 did not bear fruit either. This failure did not disappoint Mr Modi; instead, he renewed his efforts to make the business environment more attractive for foreign chipmakers. Realising the importance of semiconductors, today every country is trying to establish a semiconductor manufacturing base, with the likes of Singapore, Malaysia, Japan and Vietnam joining the race. In addition, countries with established manufacturing hubs like China, South Korea and Taiwan are trying to grow further in terms of semiconductor manufacturing capabilities. Maintains Prof Mayank Shrivastava of the Indian Institute of Science (IISc), “While several countries such as the US and Taiwan have strong prior experience, India’s advantage is that it has a vast business market, which many of the other countries embarking on semiconductors do not have. Besides, India has significant local demand, justifying the volumes required to drive this kind of initiative, and a great workforce pool required to drive such an initiative, which many other countries don’t have. So, in that sense, India is better placed compared to many of these countries.”

Adds Mr Shrivastava, “Manufacturing these advanced chips will not only make India self-reliant but will also keep us in the driving seat. Access to advanced technologies will always be the deciding factor in determining which country will lead in the future. Therefore, to become a leader or a global power, India must become a leader in advanced technologies and the basic building blocks of what drives all these technologies; i.e., chip manufacturing facilities.”

A semiconductor can be defined as a substance with the properties of both a conductor and insulator. It can conduct electricity under certain circumstances, but not always. This property of a semiconductor makes it a good medium for electricity in a controlled manner and when required. In short, a semiconductor has electrical conductivity greater than an insulator but less than a conductor.

Though all know the importance of semiconductors, very few countries earlier paid special attention to that space. Today. Taiwan, South Korea and China dominate the space while other leading manufacturers include the US.

“Vedanta-Foxconn joint venture will be the onslaught of India’s journey from chip taker to a chip maker.” - Anil Agrawal

Realising the growing importance of semiconductors and the rising demand for them, leading Asian players like mainland China, Taiwan and South Korea - which today dominate the global semiconductor space but faced a bump during the peak of the Covid-19 pandemic -- have now started scaling up their chip manufacturing capabilities and have been investing billions of dollar in the business. At the same time, the US has moved to increase semiconductor manufacturing by investing over $ 52 billion with an aim to combat China's chip-making power. What is more, almost every country is trying to establish a semiconductor manufacturing base, with countries like Singapore, Malaysia, Japan and Vietnam joining the race - not forgetting India. While some countries such as the US and Taiwan already have strong prior experience in the area, the Indian advantage is its vast bustling market which many other countries embarking on semiconductors do not have. Besides, India has significant local demand and a great work force pool, justifying the volumes required to drive this kind of initiative. Says Prof Mayank Shirvastava, "In that sense, India is better placed compared to many of these countries."

Emphasising the importance of semiconductor manufacturing for the country's economy, the Prime Minister Narendra Modi asserts, "My government is cognizant of the untapped potential fo the sector. We are committed towards the acceleration and growth of the chip design and manufacturing ecosystem in the country. An ecosystem that is built on the principle of high tech, high quality and high reliability," he adds.

With a view to giving a boost to semiconductor manufacture, the government has devised imaginative, attractive and effective promotion policies ranging from 'Make in India' to a PLI (production-linked incentive) scheme. The government has also launched semiconductor mission, 'Semicon India', with a total investment of Rs 76,000 crore under the PLI scheme. Alongside, a new electronics policy, electronics manufacturing clusters and the scheme for promotion of manufacture of electronic components and semiconductors are all targeted at boosting domestic production.

As Prime Minister Modi strongly believes that India is uniquely positioned to be an influential player in the semiconductor segment, the government's semiconductor mission aims to formulate a long-term project for developing sustainable semiconductors and a semiconductor design ecosystem in the country. A semiconductor manufacturing facility can be set up by a company which is ready to invest and find an overseas technology partner. At the same time, whether it is land, water, power, supply chain ecosystem or raw material challenges, there is no reason for companies not to enter this coveted field.

Realising this and being keen to position India as a global hub for high-tech production, the government has established the Semicon India mission and announced a Rs 76,000-crore PLI scheme for development of semiconductors. At the same time, incentives have been lined up for companies engaged in silicon semiconductor fabs, display board fabs, compound semiconductors, silicon photonics, sensors, fabs, semiconductor packaging and semiconductor design.

Under the design-linked incentive (DLI) scheme, support will be provided to 100 domestic companies working on semiconductors for integrated circuits (ICs), chipsets, system on chips systems and IP core and semiconductor design.

In December 2021, the government announced an incentive policy for the semiconductor segment under which there were different slabs for technology nodes. In this scheme, 28 nm or lower nodes were eligible for up to 50 per cent incentives of the project costs, while those from 28 nm to 45 nm were eligible for up to 40 per cent, and from 45 nm to 65 nm for up to 30 per cent. On September 21, 2022 this policy was modified and now all slabs will get flat 50 per cent incentives.

In addition, the financial support proposed for display fabs was up to 50 per cent of the project cost (subject to a ceiling of Rs 12,000 crore per display fab) but now the support has been revised to 50 per cent of the project cost on a pari-passu (equal footing) basis.

Among other aspects of the ecosystem, even the incentive for ATMP (Assembly, Testing, Marketing and Packaging) - which has received the most interest from global as well as Indian companies -- has been increased to 50 per cent, and along with ATMP for compound semiconductor silicon photonics/sensors fab and semiconductor OSAT (Outsourced Semiconductor Assembly and Test) facilities, the incentive has been increased to 50 per cent.

Enthused by the incentives, companies - domestic as well as foreign - have started considering a foray into the semiconductor segment in India. Anil Agarwal of the Vedanta group and Foxconn of Taiwan have already announced a $ 20 billion (Rs 1.54 lakh crore) plan to build up a huge chipmaking factory in Gujarat. The leading Taiwanese semiconductor company and the Indian mining giant have been clearly enthused by the incentives offered by the Indian government. Earlier, the International Semiconductor Consortium signed an agreement with the Karnataka government to invest US$ 3 billion for setting up a semiconductor plant in Karnataka. At the same time, the Tata group has also announced its decision to foray into semiconductor manufacturing. What is more, according to Ministry of Electronics and Information Technology sources, two big electronics chip companies and two display manufacturing units with investments in the range of Rs 30,000-50,000 crore are expected to be set up within the next 4-5 years.

Vedanta Chairman Mr. Anil Agarwal, who dawned a new era on the semiconductor front tweeted regarding the new plant with Foxconn describing it as 'the onslaught of India's journey from chip taker to a chip maker.' According to experts, within the next 4 to 5 years India will emerge as a global leader in the semiconductor segment. Says one expert, "India is poised to be the second largest market in the world from the perspective of scale and growing demand for semiconductor components across several industries and applications.

“India’s decades-old dream to emerge as a semiconductor hub is finally moving in the right direction. The semiconductor promotional scheme announced in December 2021 has registered excellent progress and a groundbreaking ceremony for the Indian semiconductor plant will happen in 2-3 months,” maintains Ashwini Vaishnaw, Union Minister of Information Technology and Electronics, in an interview. He adds, “I am confident that India will become a major semiconductor manufacturing nation in the next 5/6 years.”

The Minister points out that “in December 2021, our government approved a semiconductor incentive scheme worth Rs 76,000 crore to make India a semiconductor nation, the government received three silicon fab and two display fab proposals. However, they haven’t taken a call yet. But happily today, we are in a position where in the coming two or three months we should be having the first groundbreaking ceremony for an Indian semiconductor manufacturing plant.”

Acknowledging that “India needs to accelerate this journey,” Mr. Vaishnaw adds, “India needs to accept that the world is ahead of us but I assure that India would get multiple fabs.”

Visualising a bright future for the semiconductor space in India, going ahead in its journey to emerge as a global hub for semiconductor manufacturing, he confidently reveals the roadmap saying India will become chip design capital for the world soon. The Minister notes, “Today in India we have close to 55,000 design semiconductor engineers working for various companies. As part of our semiconductor programme, we have brought out a design-led scheme where engineers who want to try out their luck in designing semiconductor chips can use the common facilities which are getting developed at C-DAC in Pune and start up their venture. Whether they succeed or not, there is a great ecosystem already there so I can confidently say that within the next 5 to 6 years, we will become a great semiconductor design capital of the world. We will use that capability feed into our semiconductor manufacturing also.”

Referring to the government’s promise to the world that “India will develop 85,000 talents right from Ph Ds to MTechs, and for this a full cohort of industries, almost 48, have already signed up for this programme where the courses are now getting tailored towards semiconductor design. Almost all the big international training institutes have signed MOUs with us within the last eight to nine months.”

Maintaining that “India understands that building a semiconductor industry is not a sprint but a marathon and is prepared for the perservance required to build it in India,” Mr Vaishnaws adds, “We have prepared a very sincere partnership between industry, government, academia and research which is really required for the sustained development of the semiconductor industry in India. That is why we are committed to the long-term development path.” Insisting that “India is already home to 20 per cent of the world’s very large scale integration (VLSI) chip design engineers,” the Minister adds that “talent will be a key differentiator that will work in India’s favour. We understand that many coutnries are offering incentives, we also offer very substantial financial incentives, but when I spoke to many of the CEOs of global majors, the big differentiator that has come out is that we have committed to create and augment our talent pool by 85,000 semiconductor professionals over the next 10 years. Almost 100 academic institutions and R&D organisations have been opened to train 5,000 professionals in research, 30,000 engineers in B Tech and M Tech, and 50,000 at the floor level. So this is a very big commitment to augment our talent status.”

February 15, 2025 - First Issue

Industry Review

Want to Subscribe?

Read Corporate India and add to your Business Intelligence

![]() Unlock Unlimited Access

Unlock Unlimited Access

Lighter Vein

Popular Stories

Archives