Want to Subscribe?

Read Corporate India and add to your Business Intelligence

![]() Unlock Unlimited Access

Unlock Unlimited Access

Published: March 31, 2024

Updated: March 31, 2024

In today’s automated world, any country that aspires to a seat at the global high table needs to have a strong semiconductor manufacturing base. India has still some way to go in this respect, as it currently meets only about 9 per cent of the estimated 2026 global demand of $ 300 billion.

As of now, the country has to look to imports from chipmaking giants like Taiwan, China and South Korea. But things are changing. To set the ball rolling, three major semiconductor projects worth Rs 1.25 lakh crore have got underway at Dholera and Sanand in Gujarat, and Jagiroad in Assam.

Union Minister for Electronics and Information Technology Ashwini Vaishnav is so upbeat about the emerging scenario that he has set a target of 5 years for India to emerge as a global semiconductor destination. Giving this dream a financial push is the government’s $ 10 billion worth of incentives for home-grown semiconductor manufacturers.

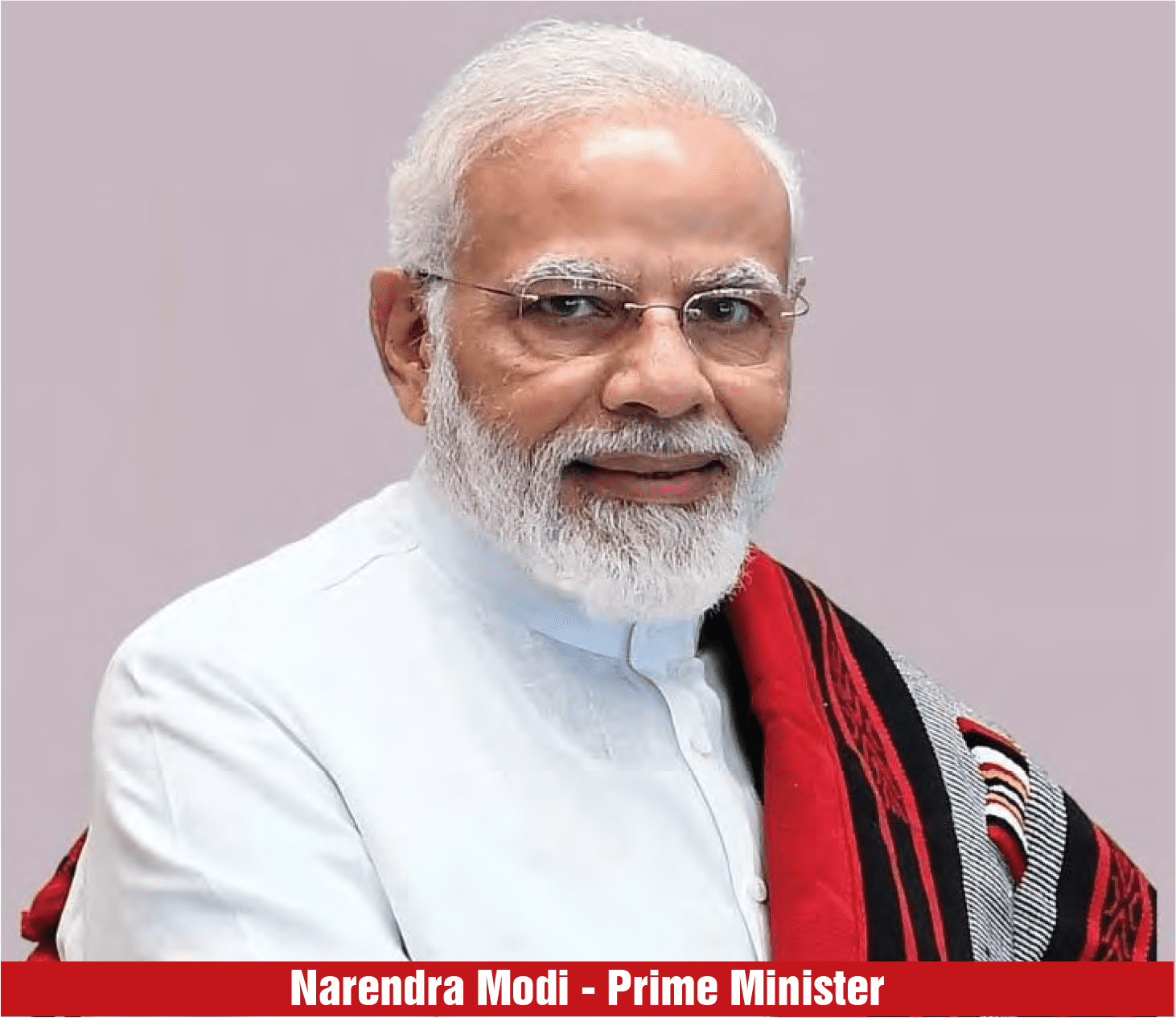

In a virtual address while laying the foundation stone at three new semiconductor plants at Dholera and Sanand in Gujarat, and Jagiroad in Assam, recently, Prime Minister Narendra Modi said, “Today, we are creating history while making a leap towards a bright future. We have inaugurated three major projects for manufacturing semiconductors in India worth Rs 1.25 lakh crore. These projects will help India become a global hub in semiconductor manufacturing.” However, Mr Modi did not specify the government’s plan to make India a global chip powerhouse in the next 5 years.

Ashwini Vaishav, Union Minister for Electronics and Information Technology, stressed that “India wants to be among the world’s top five semiconductor producers in the next five years, along with Taiwan (which enjoys 46 per cent of global semiconductor foundry capacity), China (26 per cent), South Korea (12 per cent), the US (6 per cent) and Japan (2 per cent).

According to Mr Vaishnav, India sees itself as a trusted value chain partner for electronic device manufacturers, industrial and defence electronics, power electronics — practically every electronics manufacturer which requires semiconductors to be designed and manufactured. He said some people call it ‘friend shoring’ but he preferred ‘trust shoring’ because there is global trust in India.

Though Mr Vaishnav did not specify the position India would occupy among the top five, some experts insist that if all the proposed semiconductor plants are implemented in a timely manner, India can compete with China for the third position within the next 5 years or so.

This favourable development will herald a new era of economic growth for a country that aspires not only to emerge as an industrially developed nation but to become the third most developed country globally. After all, in today’s automated world, any country that aspires to be a global power needs to have a strong semiconductor manufacturing base. However, India’s current position in semiconductor manufacturing is pathetic – as against the estimated demand of $ 300 billion by 2026, its current semiconductor manufacturing capacity is not more than 9 per cent of that requirement. The country has to depend on imports from chip-producing giants like Taiwan, China and Korea.

Maintaining that “India will emerge as a formidable semiconductor destination in the coming five years,” a confident Ashwini Vaishnav, Union Minister for Electronics and Information Technology, in an interview added that in the next five years India will join the high-stakes global stage of semiconductor manufacturing as it combines unparalleled design capabilities with $ 10 billion of incentives to draw manufacturers to set up new fabs (fabrication plants) and units that will cut the dominance of Taiwan, South Korea and China. “India’s well-crafted policies are tempting manufacturers to set up new fabs and pour investments in related sectors,” he noted.

According to him, semiconductors are an essential component of electronic devices and are used in a range of producs, from automobiles and computers to mobile phones and washing machines. India already has factories of automobile companies like from Renault-Nissan and Hyundai, computer makers such as Dell and Apple, and electronics makers like Samsung which produce TVs, washing machines and fridges, among others.

Maintaining that “now India is eyeing to step up the manufacturing value chain with high-stakes semiconductor manufacturing,” Mr Vaishnav added that the Union government’s Rs 76,000 crore worth of incentives has attracted many players, including Micron and the Tatas. The government is leveraging this and India’s geopolitical clout to become an indispensable partner for the tech ambitions of the US, which like other Western countries is looking to decouple its supply chain from China.

Pointing out that “Beijing’s draconian lockdowns had disrupted global chip supply and sent companies and governments on a hunt for alternative sources of production,” he added, “India is offering itself as a democratic and trusted alternative tech hub to China. People who were earlier thinking ‘when should we go to India’, or ‘should we go to India’, are now asking ‘how soon do we go to India’. That is the change which is happening. This means practically every big player would now like to reconsider their investment plans and come to India.”

According to Mr Vaishnav, it is very important for any developing country, especially for an economy of our size, to have a semiconductor supply chain within the country. “We have very strong design capabilities. As a corollary of these design capabilities, we must have the manufacturing capability because that is where value gets added further,” he added. “The semiconductor plans will make India self-reliant, trigger a multiplier effect on he economy and various industries, create job opportunities and spur livelihoods,” he noted. According to Mr Vaishnav, “We are focusing on niche areas where we can take global leadership. Telecom and EV (electrical vehicles) have emerged as a big segment for semiconductors. If we focus on developing and manufacturing chips used in these segments’ we can become global leaders in these two segments.” Visualising a bright future for the semiconductor space in India, he predicted that the country would become the chip design capital for the world soon. The Minister noted, “Today in India we have close to 55,000 design semiconductor engineers working for various companies. As part of our semiconductor programme, we have brought out a design-led scheme where engineers who want to try their luck in designing semiconductor chips can use the common facilities which are getting developed at C-DAC in Pune and start up their venture. Whether they succeed or not, there is a great ecosystem already there. So I can confidently say that within the next 5 to 6 years, we will become a great semiconductor design capital of the world. We will use that capability to feed into our semiconductor manufacturing also.”

At present, India plays an integral role in designing the semiconductors needed for smart phones, artificial intelligence, automotive software and industrial applications. Today, most of the country’s semiconductor ecosystem is rooted in design, not fabrication. The Indian government is determined to change that situation. In order to achieve this dream, New Delhi had in 2021 unveiled its $ 10.2 billion Indian Semiconductor Mission which aims to incentivize chip manufacturing in the country. The Centre’s dream is that the semiconductor sector should be worth $ 64 billion by 2026.

Today, there are several companies in India which are involved in the semiconductor sector. Of these, there are at least 21 companies which should be taken note of. These include Microne Technology, Moschip, Broadcom Inc, Microchip Technology Inc, ASM Technologies, Sankalp Semiconductors, Wipro, Nvidia, Intel Corporation, Marwell, Tata Elxsi and Sankhya Labs. But they are rather small in size or limited to certain segments. There are no giant semiconductor manufacturing plants in India.

The time has come when this deficiency will disappear, as suddenly there has been an unending flow of proposals to do something notable in the space of semiconductors. The three projects which were inaugurated by the Prime Minister are led by Tata Electronics, a private limited company which is part of the Tata group. TEPL is setting up two plants at Dholera in Gujarat and at Jagiroad in Assam. The Dholera plant is being set up at a cost of Rs. 50,000 crore, in collaboration with Power Chip Semiconductor Manufacturing Corporation of Taiwan, to manufacture 48 million chips a day. The commercial production of this first chip fabrication plant in the country is expected to start in 2026. The Assam plant is for assembling and packaging of semiconductors and is estimated to cost around Rs 40,000 crore. The Assam state government will invest around Rs 21,000 crore.

The Jagiroad plant in Assam is constructing a new semiconductor assembly and test facility which involves an investment of Rs. 27,000 crore and will start production by early 2026. This project will serve a number of sectors, including power, automotive, electronics, consumer and medical.

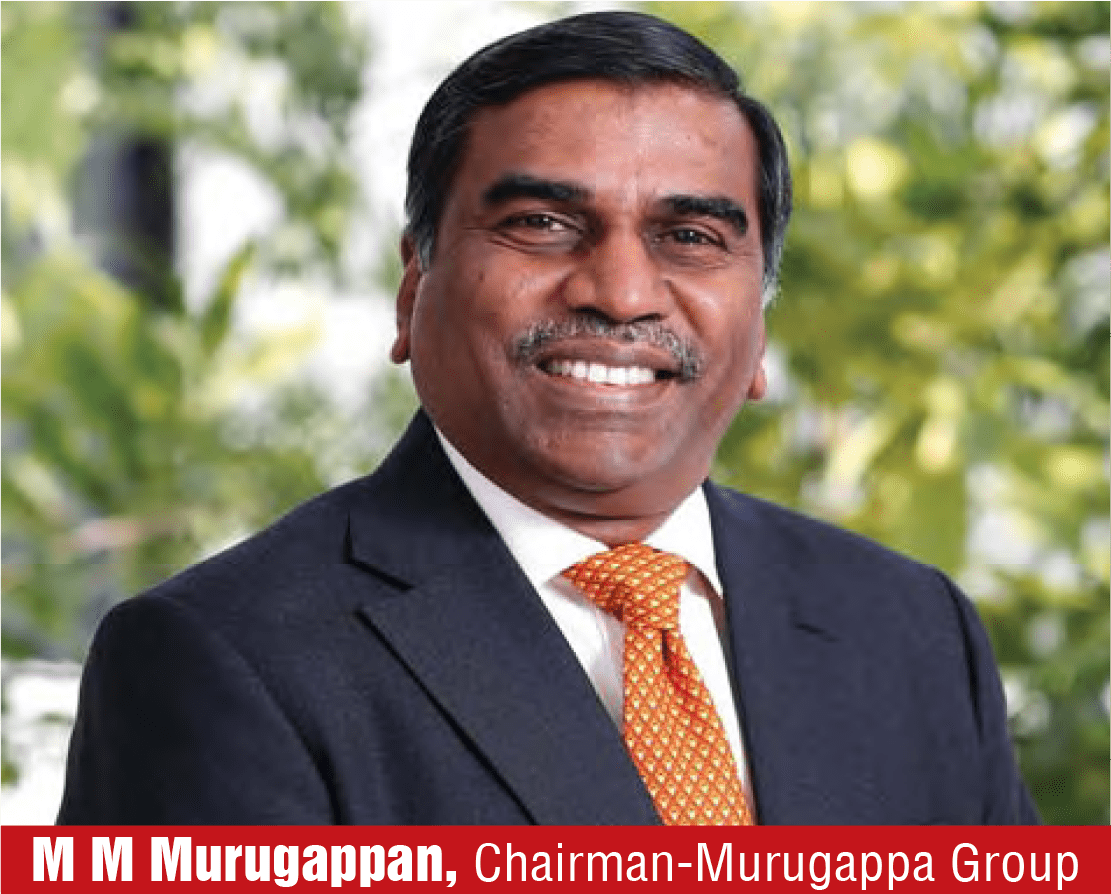

The third plant being set up by the Murugappa groupowned CG Power at Sanand in Gujarat is partnered by Japan’s Renesas Electronics and Thailand’s Stars Microelectronics at a cost of Rs 7,600 crore. This semiconductor plant will have a daily capacity of 15 million chips. Renesas will provide advanced semiconductor technology and expertise while Stars Microelectronics will provide both technology for legacy packages and training as well as enablement. In this joint venture, the Murugappa group will invest $ 205 million (92.34 per cent in equity capital), Renesas $ 15 million (6.76 per cent in equity capital) and Stars $ 2 million (0.90 per cent equity stake). Going ahead, the Murugappa group will invest approximately $ 791 million over the next five years.

Besides these three plants, the foundation stones for which were laid by the Prime Minister on March 13, 2024, there are many more proposals which are at various stages of taking shape. Kaynes Semicon's 'outsourced semiconductor assembly and testing' (OSAT) has shifted from Telangana to Sanand in Gujarat, which is emerging as the major hub for the semiconductor segment in India. American chip maker Micron and the Murugappa group's CG Power are also building chip 'assembly test marketing and packaging' (ATMP) units at Sanand.

India is separately examining a $ 11.5 billion semiconductor fabrication project by Israel's Tower Semiconductor, for which Navi Mumbai-headquartered RRP Electronics has laid the foundation stone on March 23, 2024, to construct the first OSAT semiconductor facility in Maharashtra. The company will invest $ 500 million in the 25,000 sq ft plant over the next five years. The OSAT facility, which will be set up in collaboration with a consortium of unnamed European companies, will also have an R&D centre to incorporate the latest developments in the field. RRP will seek support from the Maharashtra government to set up this project, which will serve verticals such as automobiles, power and electronics. Says a spokesperson of the company, "RRP has planned to establish a versatile unit featuring an OSAT fab foundry and manufacturing lines. After investing Rs 5,000 crore in the first five-year phase, the company will invest another Rs 5,000 crore in the second phase to scale up its operations."

The investment proposal plans to construct an $ 8 billion chip-making facility in India, aiming to capitalize on the country's burgeoning semiconductor manufacturing sector. The company is seeking government incentives to facilitate the establishment of the facility, with a focus on producing 65 nanometre and 40 nanometre chips within India's borders. Tower Semiconductor's association with the International Semiconductor Consortium (ISMC) and its application to join India's semiconductor scheme earlier faced uncertainty due to Intel's proposed acquisition. However, with the deal off the table, discussions between Tower Semiconductor and the Ministry of Electronics & IT have resumed, signalling renewed prospects for collaboration.

Tower Semiconductor's stature as a leading foundry of high-value analog semiconductor solutions makes it a compelling choice for India's semiconductor ecosystem. With a diverse clientele spanning industries such as automotive, medical, industrial and defence, Tower Semiconductor brings valuable expertise and experience to the table. What is more, ISMC has decided to invest $ 3 billion to set up a semiconductor unit in Karnataka and has signed an agreement with the state government. This plant is expected to come up within the next 2-3 years. There is also the Vedanta group's highly ambitious semiconductor plant to be set up near Ahmedabad in Gujarat, involving capital expenditure of $ 20 billion (around Rs 1.54 lakh crore). The Vedanta group had already tied up with Foxconn, a Taiwanese giant in the field of semiconductors and a supplier to Apple Inc, and the plant was expected to go on stream within the next 2 years. However, suddenly Foxconn withdrew from the project, and Akash Hebbar, global MD of Vedanta's fabrication business, said, "Vedanta is now looking to rope in Japanese partners for executing the project."

With all these plants going on stream, India could well emerge within the next five years as a global semiconductor powerhouse. Asserts Ashwini Vaishnav, Union Minister for Electronics and Information Technology, "India wants to be among the top five producers of semiconductors in the world in the next five years."

The entrepreneurial rush to set up semiconductor manufacturing plants follows the Indian government's imaginative, attractive and effective business promotion policies. To begin with, the government launched an ambitious semiconductor mission, styled Semicon India, with a total investment of Rs 76,000 crore under a PLI (production linked incentives) scheme. Runnng in tandem were a new electronics policy envisaging setting up of electronics manufacturing clusters and the scheme for promoting the manufacture of electronics components and semiconductors - all targeted to boost domestic production.

Explaining the rationale behind these semiconductor promotion policies, Prime Minister Narendra Modi said, "The government realizes the importance of semiconductor manufacturing at home. The government is cognizant of the untapped potential of the sector. We are committed towards the acceleration and growth of the chip design and manufacturing ecosystem in the country, an ecosystem that is built on the principle of high tech, high quality and high reliability."

Added Union Minister Ashwini Vaishnaw, "With these policies and the determination to build a sustainable semiconductor industry in the country, India will become the chip design capital for the world within the next 5-6 years. Today, India has close to 55,000 semiconductor design engineers working in various companies. We will use that design capability to feed into our semiconductor manufacturing also."

Of course, India's aspiration of becoming a global semiconductor manufacturing hub is not new. Way back in 2005, when Dr Manmohan Singh was the Prime Minister, the country tried to attract semiconductor manufacturing giants to set up shop here. However, an uncertain political situation, unfavourable business conditions and bureaucratic hurdles kept them away. Even under the Modi government, India's attempts to lure chipmakers in 2017 and 2020 did not bear fruit either. But this failure did not dishearten Mr Modi; instead he renewed his efforts to make the business environment more conducive for foreign chipmakers.

Realising the importance of semiconductors, several countries are trying to establish a semiconductor manufacturing base and these include Singapore, Malaysia, Japan and Vietnam. In addition, countries with established manufacturing hubs like China, South Korea and Taiwan are trying to grow further in terms of semiconductor manufacturing capabilities. Maintains Prof Mayank Shrivastava of the Indian Institute of Science (IISc), Bangalore, "While several countries such as the US and Taiwan have strong prior experience, India's advantage is that it has a vast business market, which many of the other countries embarking on semiconductors do not have. Besides, India has significant local demand, justifying the volumes required to drive this kind of initiative, and a great workforce pool required to drive such an initiative, which many other countries don't have. So, in that sense, India is better placed compared to many of these countries."

Adds Mr Shrivastava, "Manufacturing these advanced chips will not only make India self-reliant but will also keep us in the driving seat. Access to advanced technologies will always be the deciding factor in determining which country will lead in the future. Therefore, to become a leader or a global power, India must become a leader in advanced technologies and the basic building blocks of what drives all these technologies; i.e., chip manufacturing facilities."

The sudden collapse of the Vedanta group's plans raised doubts about India dream to emerge as a semiconductor force in the world in the foreseeable future. But the entry of the formidable Tata and Murugappa groups has revived the dream. Says Mr Vaishnaw very confidently, "Now we would be certainly among the top five semiconductor nations in the world."

Pointing out that "India will stand to benefit as more companies look to reduce dependence on China, as US-China tensions show no signs of ending soon," Mr Vaishnaw adds, "India sees itself as a trusted value chain partner for electronic device manufacturers, industrial and defence electronics, power electronics -- practically every electronics manufacturer which requires semiconductors to be designed and manufactured. Some people call it 'friend shoring', I call it 'trust shoring' because there is a global trust in India."

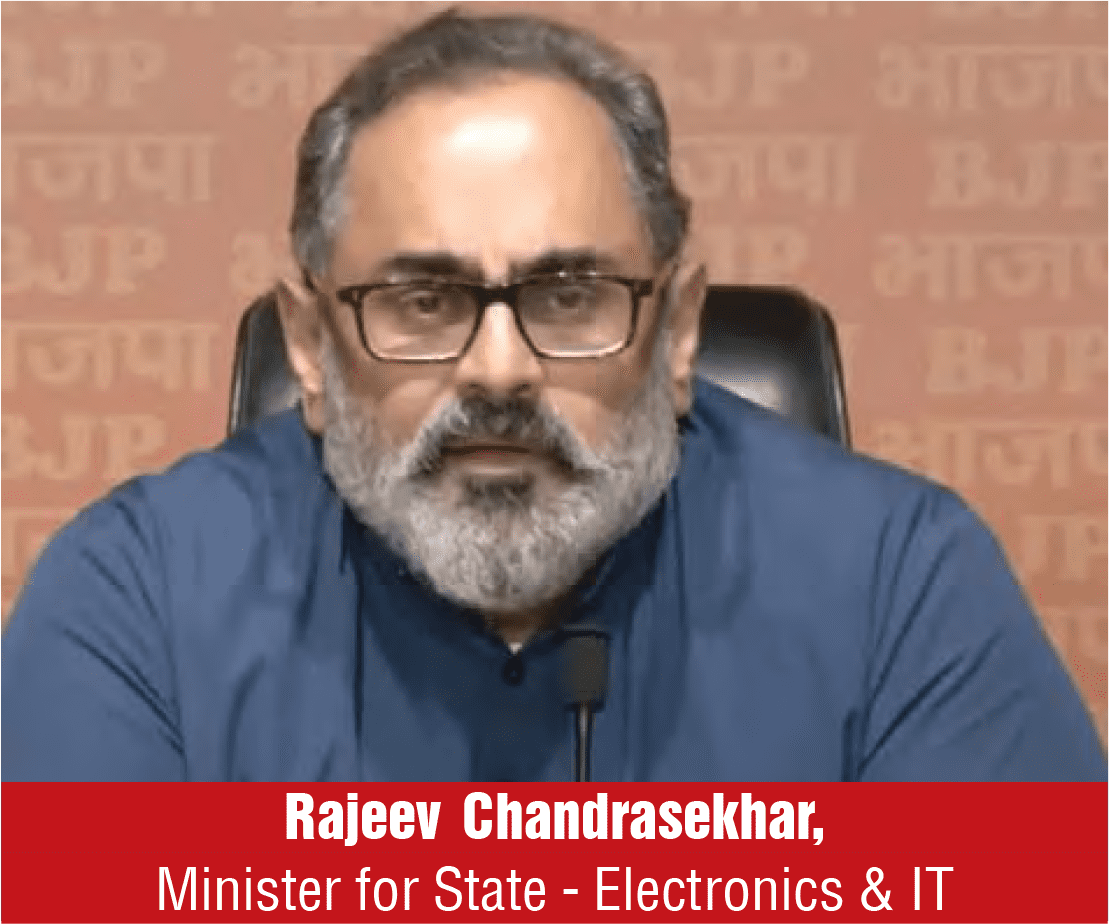

Adds Minister of State for Electronics & IT Rajeev Chandrasekhar, "Made in India chips will help create a strong and significant presence for India in the global value chain. It will make India a semicon hub for the world." Mr Vaishnav predicts that the global semiconductor sector will be worth a trillion dollars within the next seven years due to the entry of India, with a large talent pool and the current focus on ramping up its manufacturing capabilities. "This is absolutely the right time to be in the semiconductor industry and we have very rapidly gained the confidence of the entire global industry," he notes.

According to a research report, the Indian semiconductor market has already reached a value of $ 34.3 billion in 2023 and is projected to hit the $ 100 billion mark by 2032, exhibiting a compounded annual growth rate (CAGR) of 20.1 per cent during the period from 2023 to 2032.

November 15, 2025 - First Issue

Industry Review

Want to Subscribe?

Read Corporate India and add to your Business Intelligence

![]() Unlock Unlimited Access

Unlock Unlimited Access

Lighter Vein

Popular Stories

Archives